Optical Bonding

Dry film adhesive:

• Heat & pressure process to laminate glass or plastics together for strength

• Common examples are car windscreens & safety glass

• Applications: Public displays, Ruggedized cover lens

PSA (Pressure Sensitive Adhesive):

• Optically clear adhesive for flexible to rigid lamination

• Limited temperature & moisture tolerance

• Applications: Thin films or combined with additional dry film process, Foil PCAP application to cover lens

Wet bond - Viz-Bond® :

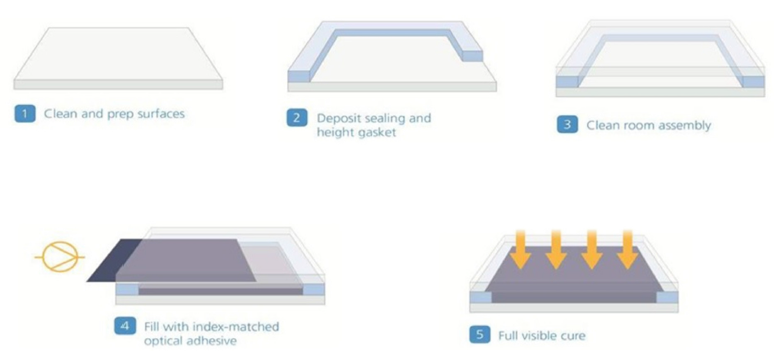

• Cold process without pressure

• Application: Direct bond to displays or integration with cover glass / Touchscreens

• Touchscreen or display ruggedised protection

Why Viz-Bond Bonding ?

• Lamination without heat or pressure

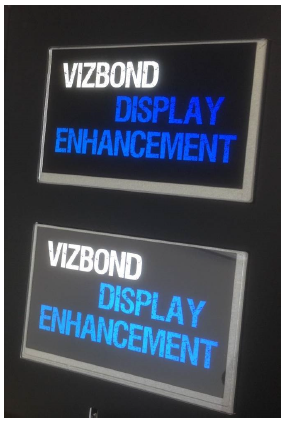

• Index matching and elimination of air gaps optimizes optical performance

• True black off appearance

• High level of mechanical performance & impact strength

• Full integration with LCD’s & Touchscreens

• Greater colour contrast through the colour spectrum

• Sunlight readability

Viz-Bond in a nutshell:

• Optical Filters proprietary direct bonding system

• Wet laminating system with broadband energy cure. UV through to visible (350-550nm)

• Refractive index matched n = 1.5 fill material provides perfect match to most display enhancement materials

• Vented spacer gasket system gives minimal shrinkage

• Yield is 95-98% but the system is also fully re-workable

• Allows full integration from the display source to the front cover lens or touch screen

• Fully curable through silkscreen printing border to give the “iPad” look

Viz-Bond Process: