4-,5-, and 8-Wire Technology

Resistive analog touch screens are normally available with 4-, 5-, and 8-wire circuitry.

4-Wire Touch Screen

4-wire touch screens, suitable for small or medium sized products, such as PDA, ,hand-held systems, utilize four edges of the screen presenting X+, X-, Y+ and Y- lead outs. When contact is made, X/Y read-outs are then read by the controller and converted into the correct coordinates.

5-Wire Touch Screen

5-wire touch screens can be produced in screen sizes from 3" to 24". Resistive touch screens are suitable in many different systems and different environments.

In the 5-wire touch screen, the top layer is a sense layer while the main circuitry is located in the layer beneath.

8-Wire Touch Screen

8-wire circuit structure is well suited for screens from 6" to 22". The function is much like that of 4-wire circuitry; with the major difference that 8-wire offers 4 additional screen read-outs and circuit protection. These additional read-outs can be used to further adjust possible distortion on the corner or edge of a larger screen.

Glass-Film-Glass (GFG)

AMT also successfully developed resistive touch screens with a thin glass and a heavy duty material mounted on the surface, which AMT has named GFG (Glass-Film-Glass) touch screens. The surface of such GFG is even more resistant to scratch, offers high temperature performance and cab be easily cleaned.

.jpg) T

T

here are two designs for GFG touch screens; one is using a 0.2mm thin glass on top of the resistive touch screen, and the other is using a HD (heavy duty) film laminated on the top of the resistive touch screen. Both of the materials, thin glass or HD film, are featured with the advantage of anti-scratch. When applying thin glass with clear surface finish, the hardness will reach Mohs 5, while using HD film, whether it concerns a clear type or AG type of surface finish, the hardness will be higher than 9H. GFG touch surface coatings could be clear surface or Anti-Glare surface finish. GFG touch screens are resistant to not only scratch and abrasion but also most chemicals, which makes GFG touch screens appropriate for the following applications:

• Industrial

• Medical Equipment

• Equipment for Food Industry

• Adverse and severe working circumstances such as gas station or chemical plant

• Various marine, haulage or aero transportation operating systems

If the GFG is to be mounted onto equipment for outdoor use, it is also customizable to treat the GFG with low-reflection process, called GFG LR.

Low Reflective (LR)

The luminance emitted by an average LCD reaches 200-350 nits approximately. If we place such LCD's outdoors and in sunlight ( brightness is around 10,000nits), the reflected light will be too bright to keep us from clearly seeing what’s on the LCD. As researched, the luminance of a LCD for outdoor use must be greater than 200fL (686 nits) to make an acceptable vision on it. As a result, many enhanced LCD's, whether built with polarizers or with increased luminance, have emerged in the marketplace.

.png)

AMT successfully developed Low Reflective Touch Screens compatible with any average LCD. An ordinary LCD used in conjunction with AMT’s Low Reflective Touch Screen will effectively reduce light reflectivity to so low as <1.5% therefore the screen will be clearly visible. The core technology AMT applies is the ability to reduce the reflection of the touch screen while reinforcing the light transmission of the touch screen at the same time. Developers need not modify the LCD to make his/her product fit for outdoor use.

In comparison to the reflectivity of other ordinary resistive touch screens around 16%~22%, AMT presented Low Reflective Touch Screens of the CR (Circular Polarizer) series of reflectivity lowered to <1.5%. AMT LR touch panels are available with anti-glare and clear on surface finishes and sizes range from 3" to 19".

Applications

• Hand-held product

• Industrial products

• Notebook computers for outdoor use

• Automotive products

• Others

Design Points

• Good for the outdoor use or under bright light due to low reflection

• High transmission rate reaching 76±3% whether 4-, 5-, or 8-wire

• Size: 3"~19"

• Clear surface and anti-glare surface treatments for choices

• Reflective <1.5%

• AMT’s standard touchscreens can be replaced with LR touch panels

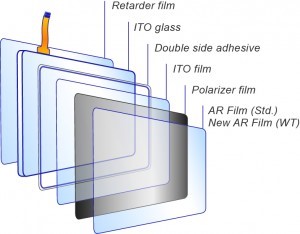

Construction

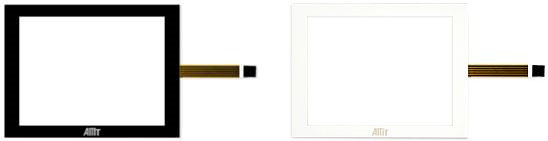

Framed Touch

Framed Touch is an innovative design of a true flat touch screen. It takes no Decor Film added to the touch panel to have a true flat surface on the touch screen. It is also a simplified version of AMT’s existing true flat touch design, the Touch Window. The frame can be printed black or white as well as a customer’s logo. Framed Touch requires only the tail design similar to conventional resistive touch panels and needs no particular design. Comparing to all existing designs, Framed Touch has the following advantages:

• Better light transmission rate

• More simple construction

• AG or clear surface customizable

Construction

Design Options

• 5-wire design

• Glass for backer

• Various thicknesses for selection

• Similar tail outgoing to conventional resistive touch panels